IMPROVED OVERPRESSURE CHAMBER

UNR CAPSTONE PROJECT - IN PROGRESS

Problem Statement

Our team is working with Advanced Materials and Devices (AMAD) to improve their Friedlander wave–producing overpressure simulation system used for blast sensor testing. The current system operates by igniting a balloon filled with an oxygen–acetylene mixture that, upon combustion, generates an overpressure wave measured by multiple sensor configurations. However, the existing design lacks the ability to generate controlled, repeatable overpressure waves, has a rudimentary control system, and places the ignition system outside the test chamber, creating safety concerns for long-term use. The ideal version of this system would allow for safer operation, improved control of the gas mixture, and the generation of consistent overpressure wave generation to support reliable sensor testing. Without addressing these limitations, the system risks producing inconsistent data and poses ongoing safety concerns, which can limit the effectiveness of sensor development intended to reduce traumatic brain injury risk. This project proposes the design and implementation of an improved overpressure simulation system that enhances operational safety, integrates controlled gas mixture and ignition mechanisms, and enables repeatable overpressure wave generation to support reliable blast research and sensor validation.

Key Motivation

The primary motivation for this project is the need for an overpressure simulation system capable of producing repeatable and well-characterized overpressure wave data, which is essential for validating and calibrating overpressure sensors. Reliable and consistent experimental data enable meaningful comparison between sensor configurations and support ongoing research efforts aimed at improving overpressure exposure monitoring. By enhancing the safety, control, and repeatability of the system, this project directly contributes to the development of more robust experimental tools for overpressure research without extending beyond the system’s engineered scope.

Prior Knowledge and Background Information

The project team’s prior knowledge includes coursework and practical experience in system dynamics and controls, electrical circuits, fluid dynamics, thermodynamics, and mechanical design, all of which are directly applicable to the design and analysis of a controlled overpressure simulation system. These foundations support the modeling of gas flow and combustion behavior, the integration of ignition and sensing hardware, and the development of control strategies required to achieve repeatable overpressure wave generation. This background provides a sufficient technical basis for the successful design, implementation, and evaluation of the proposed system.

Concept Design

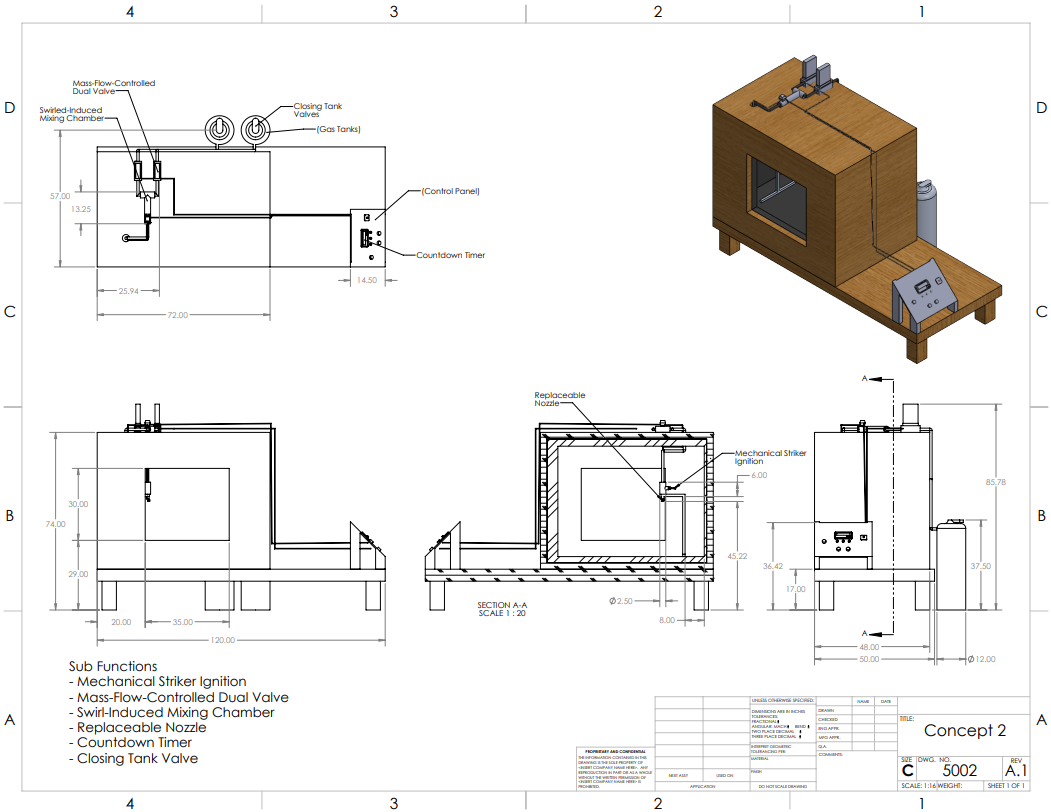

Below is a concept design of the Overpressure Chamber, which includes the newly added and improved subfunction component intended to enhance both safety and repeatability. The designs were created in SolidWorks and will continue to be refined as the project progresses. Subfunction callouts and basic dimensions have been included to clearly communicate the overall layout and intent of the design.

Concept Design of the Improved Chamber with Basic Dimensioning and Callouts of the Subfunctions