MEDIUM QUAD CORE GRIPPER

HAMILTON INTERNSHIP PROJECT

Project Summary

Objective: Resolve the clearance and detection limitations of the Quad Core Gripper (QCG) while maintaining cross-platform consistency.

Key Impact

Increased sensing bracket sensitivity by ~30%

Achieved reliable detection and pickup across platforms

Validated durability over 246,000 total cycles (123k per instrument)

Delivered full redesign, validation, and release in 4 months

Engineering Contributions

Determined allowable bracket shortening using CAD analysis and positional measurement studies

Built a decision table comparing design options and resulting clearances

Performed flexural force calculations to evaluate compliance vs. internal spring force

Redesigned sensing bracket geometry to restore compliant detection behavior

Verified final dimensions and manufacturability with vendors while minimizing cost

Developed a full validation plan covering force testing, detection accuracy, pickup reliability, and endurance

Executed integration testing on two instrument platforms

Wrote test methods and resolved hardware–software inconsistencies with engineering teams

Diagnosed and coordinated fixes for software defects discovered during validation

Core Skills Demonstrated

Mechanical design • CAD analysis • tolerance/clearance studies • force modeling • validation testing • cross-functional engineering • vendor coordination • technical documentation • rapid problem solving

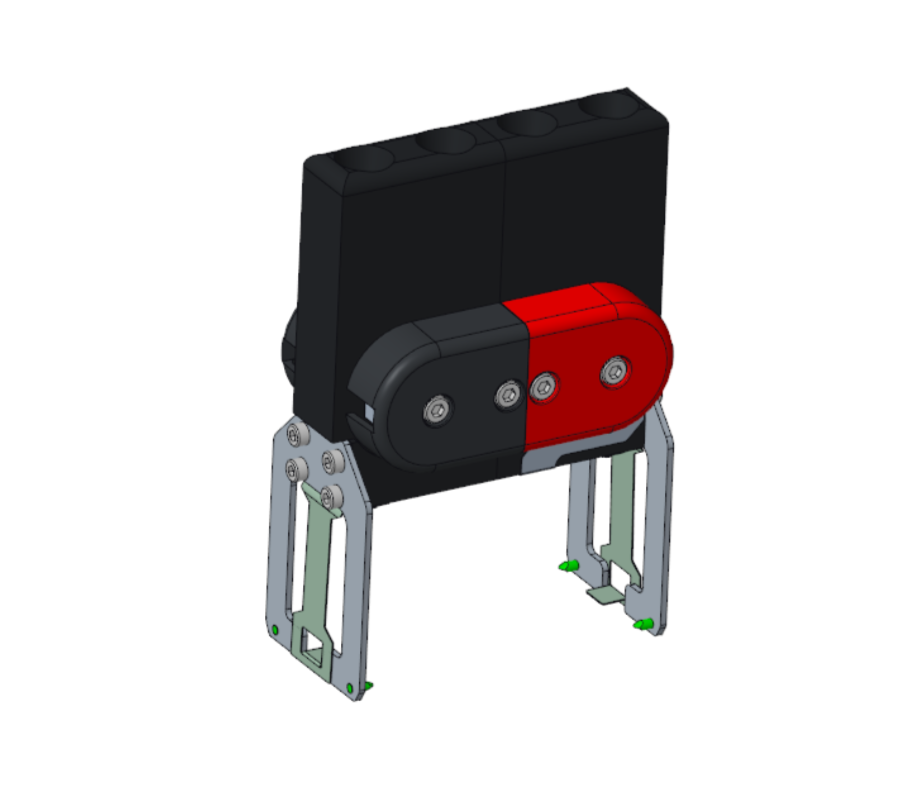

MQCG Isometric View

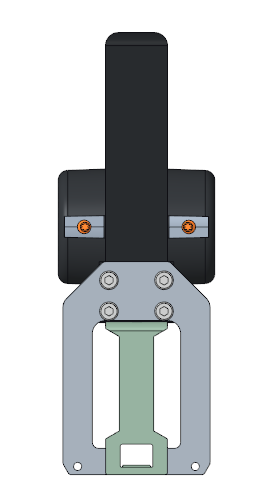

MQCG Side View

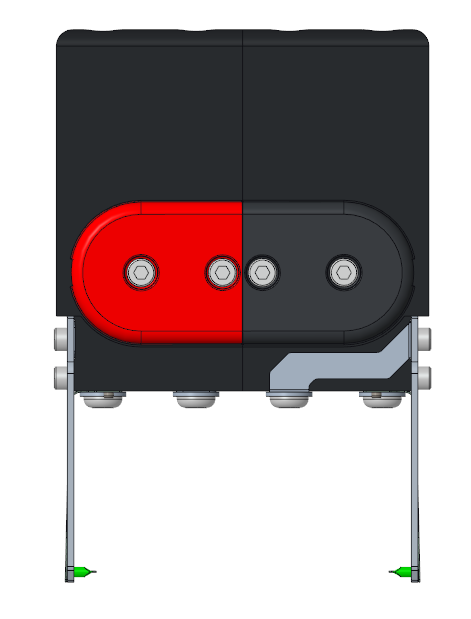

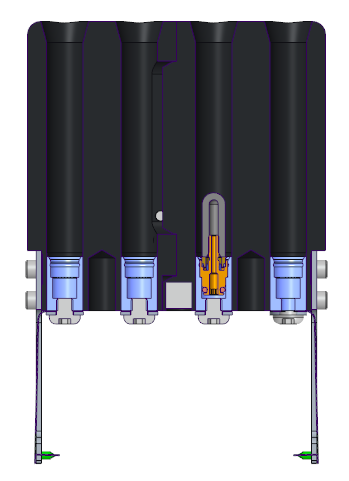

MQCG Front View

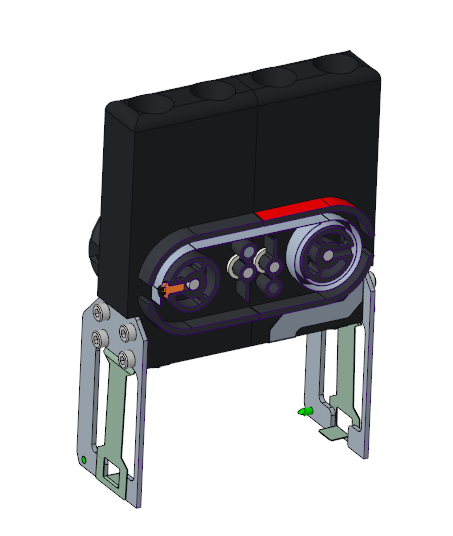

MQCG Internal Spring

MQCG Section View